Home>Product>Sunflower oil solvent extraction plant>D.T.D.C.system in sunflower oil solvent extraction plant

Home>Product>Sunflower oil solvent extraction plant>D.T.D.C.system in sunflower oil solvent extraction plant

D.T.D.C.system in sunflower oil solvent extraction plant

Sunflower oil solvent extraction plant / Chat on line / Give me a price / Date:January 10, 2019

The D.T.D.C system is short for Desolventizing Toasting Drying and Cooling Tower, which is used in sunflower oil solvent extraction plant. The main function of D.T.D.C system is remove the solvent in wet meal and obtain high-quality meal.

As the whole name shows, D.T.D.C system includes desolventizing, toasting, drying and cooling, four steps to process the wet meal that is from the solvent extractor.

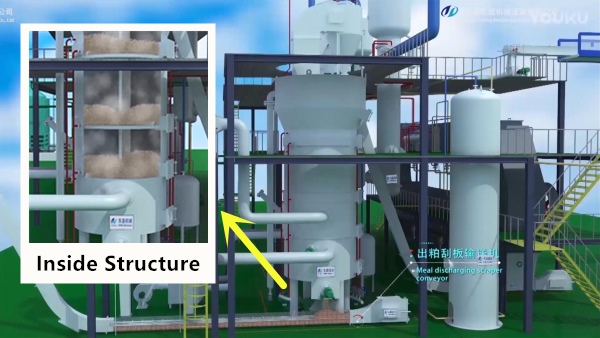

D.T.D.C tower and its in side structure

D.T.D.C tower and its in side structure

Main Structure of D.T.D.C system:

As shown in the picture above, D.T.D.C tower contains layer, sieve-board, main axle, scraper, automatic material door, base, driver structure.

Working Principle of D.T.D.C system:

The wet meal is sent into desolventizing-toasting layer by screw conveyor, and firstly reaches on the heating plate of the first pre-desolventizing layer. Then the wet meal is heated by steam to remove part solvent. With the turning of the paddles, material drops to the next pre-desolventizing layer, then to another.

And after three levels, material drops to the main desolventizing layer. There are some direct steam nozzles on the chassis of the layer which can spray direct steam with the pressure of 0.05~0.1MPa, thus the solvent in wet meal can be removed completely. After desolventizing, the moisture content in meal is high, so drying meal with hot air is the last step.

D.T.D.C system can help you get high sunflower seeds meal and solvent that can be recycled. It is the second main equipment in sunflower oil solvent extraction plant. Any questions, please leave a message!

contact us

Kindly leave your message in below form. Our engineer will contact you ASAP once we got your message.

Call us

Call us Chat online

Chat online